Born for art - focusing on high-end wall coatings

BAYAG ®, As a high-end wall coating manufacturer, it is from Italy. It has a high-end automated production workshop and a large laboratory with complete equipment. It focuses on high-tech research and development as the leading role, and the production of environment-friendly art coatings as the core strategy. It provides a continuous stream of high-end art coatings products for the market and creates an urban ecological space. Diversified style and color matching, high-end creative inspiration. Meet different levels of customer needs, BAYAG ® High end art coatings create high-end art walls and create a model of high-quality life.

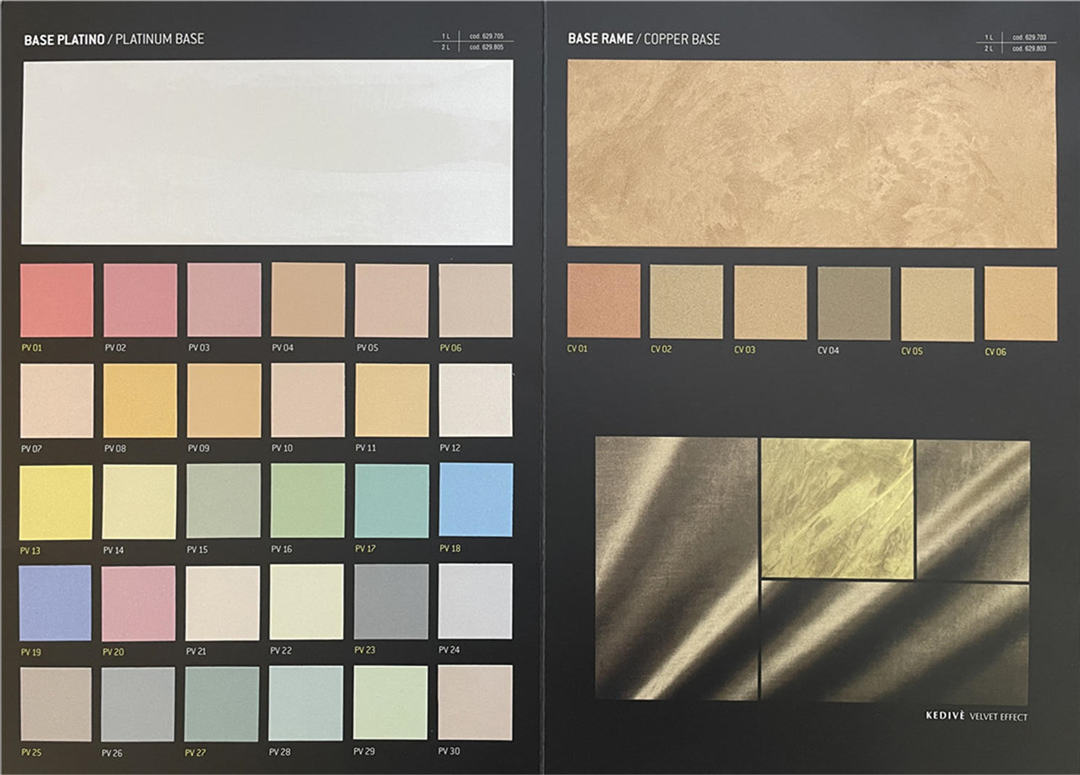

characteristic

Healthy, formaldehyde free, diversified patterns, scrub resistant, refractive effect, texture, three-dimensional, fire resistant, moisture resistant, economical, practical, durable, seamless, colorful, durable, irregular construction

Tooling and home decoration

BRAND PROFILE

BAYAG ® Brand operator of imported artistic coatings in China, with garden style factory and advanced experimental facilities. With years of practical experience in wall coating manufacturing and innovative technology, we have independently researched, developed and produced. It mainly focuses on the R&D and production of environment-friendly artistic coatings, with polymer fusion technology as the leading technology, and establishes a local technology laboratory to develop environment-friendly lotion, additives and other auxiliary materials. At the same time, a color studio was established to create a high-end integrated color system to achieve a three-dimensional artistic decoration effect, breaking the phenomenon that traditional paint can only present a single, flat wall. At the same time, the Italian design team is employed to carefully build the product packaging system, from raw materials to outer packaging, in order to give you high-end art enjoyment. and the whole process is strictly monitored and controlled, which is put on the Chinese market. BAYAG ® The brand of Poyango Art Paint focuses on the national market and radiates to provincial capitals, municipalities directly under the Central Government and the first, second and third tier large, medium and small cities. Integrate high-quality resources. By focusing on the development of packaged supporting services, we will expand our business scope to attract more partners, enhance enterprise vitality, better meet the market consumption trend, quickly address the demand for purchasing power, create a one-stop packaged consumption experience, and lead the industry.

Detailed explanation of construction method steps:

Ingenious design, pinnacle techniques, create a comfortable living life.

【Polishing process】

First: use a roller to apply the same color primer of velvet paint.

After the primer is dry, roll the velvet material for the first time. This step requires the entire bottom surface to be smooth, evenly rolled, and not to miss the bottom.

Then, after waiting for the whole body to dry out, we roll-coated the velvet material a second time and polished the velvet texture with a sander.

Continue to wait for the surface of the material to dry up to 50% or 60%, and then continue to polish it with a sander to make the texture fine, evenly patterned, and layered, with a fluffy texture like swan wings, soft and shiny.

Finally, when the paint surface is 80 to 90% dry, do a slight leveling and trimming. A good velvet material will give the overall wall a feather-like visual effect after construction, with a delicate texture and light luster.

[Vertical pattern process]

First of all, we use a roller to apply the same color primer of velvet material once, and be careful not to leak the primer during the rolling process, and apply it evenly.

After the primer is dry, we start to roll-coat the velvet material for the first time. The entire surface is required to be flat and smooth during the rolling process. After the first coat is dry, roll-coat the velvet material for the second time, and then use the sander to go up and down. Sand out the texture.

After the material is 50% to 60% dry, we use a batch knife, one knife at a time, and the texture effect is collected, so that the overall wall surface shows a swan feather-like luster, with distinct layers, smooth and delicate. The whole process requires the construction plane to be flat and smooth, with uniform strength.

[Fine lines craft]

First, use a roller to apply a primer of the same color as the velvet material.

After the primer is dry, roll the velvet material for the first time. This step requires the bottom surface to be flat and smooth, with uniform strength, and not to leak the bottom.

Then, after the first pass of the material is dry, continue to roll on the second pass of velvet material.

When the velvet material is not dry, we need to use a professional brush, from top to bottom, brush the fine grain texture in order with uniform strength, pay attention to the order and direction to keep the same, so that the entire plane texture is uniform and clear.

Renderings show:

Pioneer design inspiration comes from BAYAG.

The smart room displays high-end quality, and the elegance of the Swan Lake is highlighted.